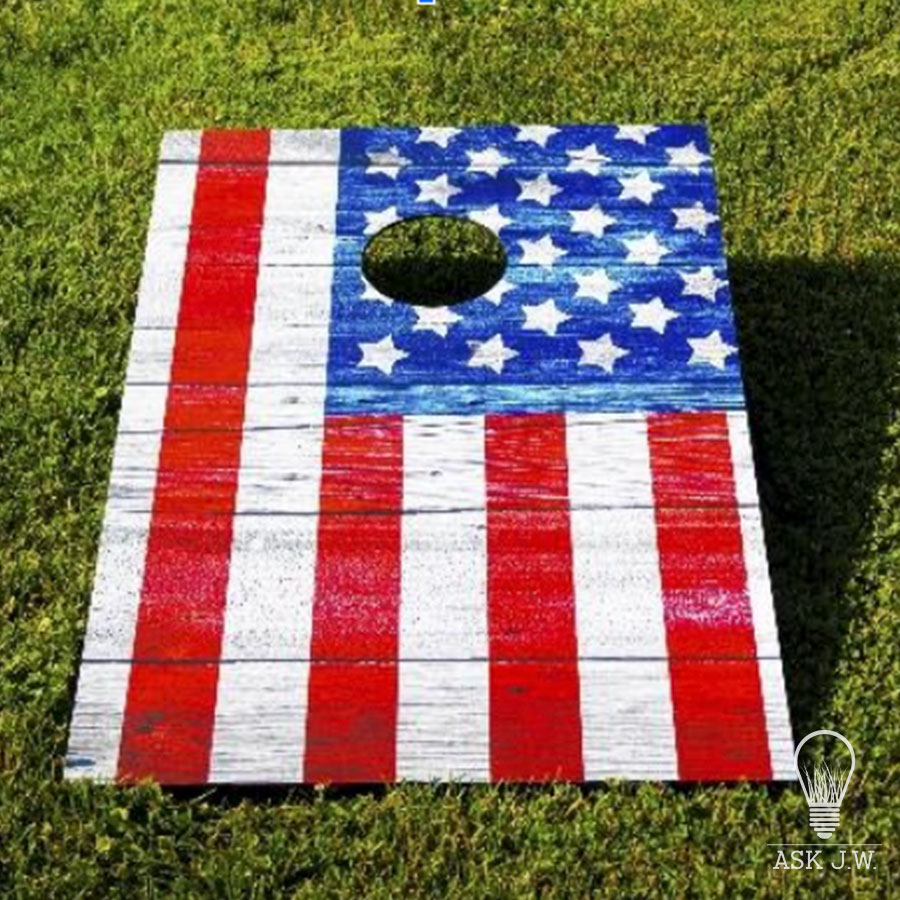

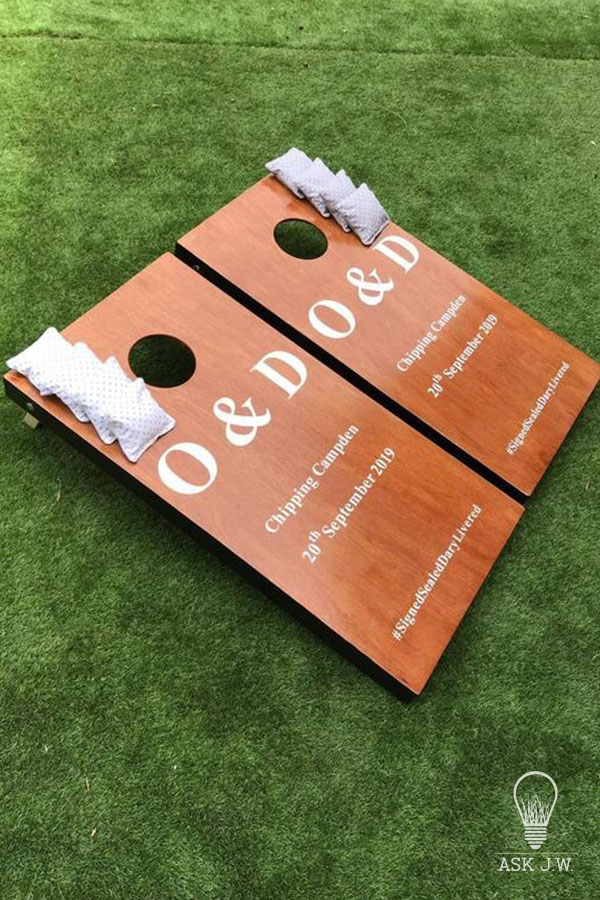

Horseshoe, bocce, lawn darts, croquet, badminton, and Frisbee are several lawn games we all grew up playing. The game cornhole has become one of the most popular lawn games across the nation. Cornhole is a lawn game in which 16-ounce bags filled with corn kernels are tossed at a raised platform 15 feet away. The game is played with two platforms. The platform has a hole constructed in the far end of it. The platform is usually made of plywood and is tilted at one end to face the players. A bag in the hole scores three points. One left on the board scores one point. The player that reaches the score of 21 wins. Cornhole is fun and exciting to play, but it can also be damaging to the surface it is played on. This month, Ask JW will teach you how to install cornhole pads to help preserve the longevity of the surface it is played upon.

Cornhole & Natural Grass

Cornhole platforms can be damaging to any surface it is placed upon. Excessive movement, vibration, and pressure can easily damage natural grass within hours. The problem with playing lawn games on natural grass is the time it takes for re-growth. With little to no maintenance on these areas, the cornhole platform will start to work its way into the subbase, resulting in playing on dirt.

Synthetic turf is perfect for all lawn games, especially cornhole. Synthetic turf can withstand cornhole platform settlement. The backing of the turf will not allow the platform legs to dig into the subbase, which is crucial for the platform to remain somewhat level. It also allows the surface to remain clean and free of dirt. Commercial centers are using synthetic turf in areas where high-traffic lawn games are present.

Lawn Games & Pile Height

Pile height is crucial when choosing the right synthetic turf for your lawn games, especially cornhole. Cornhole locations get beat down by excessive use. Using a lower pile height in these areas will give increased longevity to the area and will also keep the area looking nice. When continuous foot traffic is allowed in small, condensed areas, premature matting may occur. Maintenance of infill levels is recommended before and after cornhole to keep the synthetic turf looking nice. I will touch on infill levels later in the column.

I recommend placing putting green materials under the cornhole game area. Putting green material, especially nylon putting green material, is constructed with a low pile height and has successfully been used under high traffic areas in commercial playgrounds. The nylon fibers are more aggressive than PP or PE and will prevent excessive wear in the platform area.

Cornhole & Synthetic Turf Installation

When playing cornhole on synthetic turf landscape, it is important to understand that excessive use may cause the turf to flatten or become matted. The cornhole stance assumed while tossing the bag puts a beating on the turf fibers. A little maintenance will keep the fibers vertical and looking the same as the surrounding turf. Make sure you plan out the area to ensure the cornhole platforms are in the desired position. Once the locations are established, it is time to lay out where the putting green materials will be inserted.

Layout

When playing cornhole on synthetic turf landscape, it is important to understand that excessive use may cause the turf to flatten or become matted. The cornhole stance assumed while tossing the bag puts a beating on the turf fibers. A little maintenance will keep the fibers vertical and looking the same as the surrounding turf. Make sure you plan out the area to ensure the cornhole platforms are in the desired position. Once the locations are established, it is time to lay out where the putting green materials will be inserted.

Large chalk box – It is advantageous that you snap chalk lines when cutting sections for your layout of synthetic turf. It is a good habit to have and will lower your waste percentages. I prefer a large chalk box instead of a small one. The large chalk box will give you more visible lines to cut on, and you rarely need to fill up when needed. I recommend using lime green chalk that can be purchased at Home Depot or Lowe’s. The lime green is easier to clean up than other colors and is similar to the turf fibers if you have a spill.

Cutting & Removal

When the layout is complete, double check your measurements before cutting into the landscape turf. Take a sharp knife and position it down into the fibers all the way to the backing.

Cut along the chalk line avoiding cutting any fibers. It is crucial to angle the blade of the knife so that it cuts under the turf and into the backing. Change the blade every three feet. The infill will dull the blade very quickly. Once you have reached the end, do the same for all sides.

Step 4. Grab the overhanging waste with one hand while you place the blade down into the side of the hardscape

Placement of Putting Green Materials

When the two sections are clean of debris, it is now time to cut and place the putting green materials. It is important that you place the two sections in the same direction. The grain of the PG materials may show if they are placed at different angles. I recommend temporarily securing the sections with turf nails so that the sections do not move while cutting. Once secured, cut the PG material into the landscape turf like you would cut fringe on a putting green installation. Below is a video showing the slide cut method. This allows the blade to cut the backing/bottom edge while folding the cut edge of the PG towards you while slightly pulling.

Infill Placement

Infill placement is crucial for longevity of synthetic turf, including putting green materials. I recommend placing the infill to the top of the PG surface on the cornhole pads. This will prevent premature matting of the fibers, which may cause depressions in the area.

Please read the column “Perfecting Putting Green Surfaces Part 2”. This will teach you how and why it is important for the infill to be placed at the correct levels.

Complete Cornhole Beauty!

I truly hope you are enjoying my blogs and columns. For more information regarding the slide-cut method, or to schedule a training, please contact J.W. at 888.846.3598 or email AskJW@SGWcorp.com

Suggestions for the use of ASK JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither ASK JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.