Dropspreaders & Synthetic Turf

A drop spreader is crucial to have for installing synthetic turf correctly. Placing infill into synthetic turf creates ballast and provides longevity to the system. There are many types of drop spreaders that can be used. Knowing how and when to use one is critical for many reasons. This month, ASK JW will explain what type of drop spreader is recommended for landscape synthetic turf and how to use them. We will also explain many topics in previous columns that go hand in hand with using a drop spreader.

Ballast & Drop Spreaders

Wherever I travel, I speak on the importance of ballast. In my previous columns, I have written about infill ballast and its role in completing a stable synthetic turf system. In the turf world, ballast is used to weigh down the turf, prevent wrinkling, and give the entire turf system stability and longevity. Properly placing infill assists the turf fibers in maintaining a vertical position. Having a quality drop spreader will help in doing just that.

Wrinkling

I often tell installers that a good drop spreader prevents wrinkling. They don’t actually prevent wrinkles, but using them properly along with infill does. When turf installers ignore using drop spreaders for equally placing infill, wrinkles may occur. Hot climates require NO CHEATING on placing infill into your synthetic turf system. I have seen contractors deliver 10% of the infill required to ballast the turf system. If the manufacturer requires 1 1/2 pounds of infill per square foot for the product you are installing, it is YOUR responsibility to place what is needed. Placing infill has many benefits to your turf system, not just keeping the fibers upright but assisting in ballast, which is the #1 prevention of wrinkling.

To gain additional knowledge on turf wrinkles, please read the columns attached below.

https://syntheticgrasswarehouse.com/avoiding-the-putting-green-wrinkle-effect/

https://syntheticgrasswarehouse.com/askjw/preventing-wrinkles-turf/

What is a Drop Spreader?

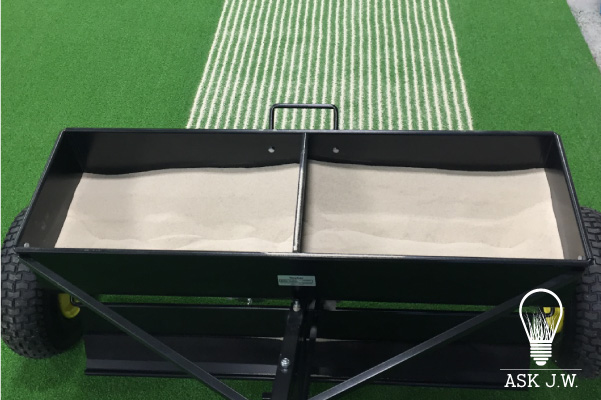

A drop spreader is a container that is usually mounted on two wheels and designed to drop a measurable path of granules onto a surface. Most drop spreaders come with an elevated handle so a person can easily walk and push along the surface. When using a drop spreader for synthetic turf, the drop spreader drops infill granules vertically into the fibers at an evenly distributed path.

Even though you may own a good drop spreader, placing too much infill at one time may trap the fibers. When this happens, your installation may turn out ugly.

Higher capacity sports field spreaders with the whirlybird effect work well for sports field systems due to the force of spread capacity from mechanics and hydraulics.

I do not recommend using a landscape “whirlybird” type of spreader for landscape synthetic turf. It does not place the infill consistently like a drop spreader. The whirlybird spreader, as I call it, may cause a build-up of infill due to its ability to throw/spread out instead of drop down evenly in its passes.

JW’s Favorite?

Scotts Classic Drop Spreader!

For landscape turf installations, I recommend purchasing a smaller to medium drop spreader. The average backyard install is 450 sq. ft. I recommend purchasing a size that will serve your average installations and is easier to store. Most supply houses and Amazon carry my favorite, the Scotts Classic Drop Spreader, which costs approximately $80.00. I have used the Scotts Classic Drop Spreader for decades, and they are pretty much indestructible. Don’t let the plastic look fool you. It can easily hold up to 100 lbs. They are very strong, everlasting, and made of composites that withstand hot and freezing temperatures.

The Scotts Classic Drop Spreader comes ready assembled with an adjustment setting gauge that allows heavy-to-light spreading capabilities.

Larger Projects

For projects that are approximately 1000-3000 square feet, I recommend using multiple (more than one or two) Scotts Classic Drop Spreaders or purchasing a larger drop spreader. Make sure you do your due diligence when you invest in a turf infill drop spreader. I have used quality metal-constructed drop spreaders in my career, and many times, silica sand, zeolite, and coated turf infill had caused the bottom mechanism to jam up after many uses.

The granules break down and become fine from the auger, which clog the lower sliding hatch, causing the hatch to either stay open or stay closed. This may be due to the drop spreader being designed for soft fertilizer.

“Before starting infill placement, I recommend figuring out how many square feet you have. How many pounds of infill does the product require? Then send that number of pounds of infill to the project. To create a completed system that requires Sq. ft x Lbs. of infill to be placed, the frontline must understand this in its entirety”.

JW

Compaction Equipment

Now that you have purchased a quality drop spreader and are ready to place the infill, it is crucial to place the infill when the turf is secured tightly to your compacted surface. If the turf surface is loose, this may cause pre-mature wrinkles when the temperatures rise

I recommend placing infill in the early mornings to stay ahead of the rising temperatures. Rising temperatures create wrinkles. I have been on large projects where early in the morning, the turf lays flat. Every hour when the temperature got hotter, more wrinkles started to appear. By lunchtime, they had multiplied.

Once you start placing infill into wrinkled turf, the chances for the infill to weigh down the wrinkle while in its expanding/contracting mode is very slim. I recommend waiting until the temperatures lower and placing the infill when there are no visible wrinkles.

Backfilling & Lifts

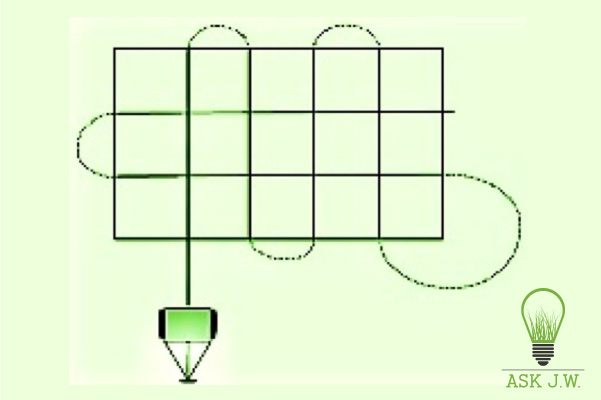

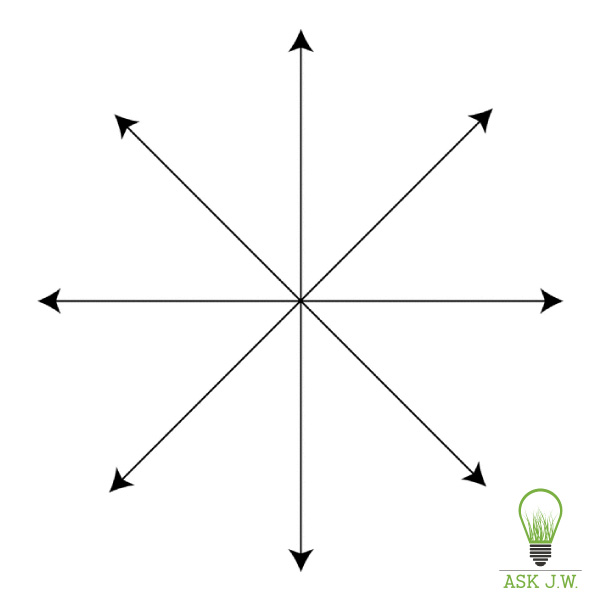

When placing infill from a drop spreader, I recommend placing it in a pattern. In my previous columns, I talk about placing infill in all directions. You can either place going “North to South,” “East to West,” or use the “Clock” method that I teach in the field.

Infill Placement Example

Make your passes like clock numbers

Pass #1 – 6 to 12

Pass #2 – 3 to 9

Pass #3 – 1 to 7

Pass #4 – 11 to 5

Pass #5 – 2 to 8

Pass #6 – 4 to 10

Infill Placement & Moisture

Precipitation (rain, snow, sleet, or hail) can cause havoc on your putting green synthetic turf installation. Have you heard the saying, “Fail to Plan, Plan to Fail?” If you intend to place infill into putting green materials that have any moisture within it, it will have a traverse effect on how the ball rolls and stimp meter speeds. Sending your teams out to install infill when there is a chance of precipitation will cost you time, money, and lots of frustration.

When moisture meets synthetic turf fibers, it sticks to the fibers and prevents infill from dropping into the base of the synthetic turf. Moisture can prevent infill materials from doing their job. Placing infill when synthetic turf fibers are wet is like trying to get beach sand off your feet when you leave the beach.

Successful synthetic turf contractors stay in touch with future weather patterns. I recommend checking with your local weather prior to any synthetic turf installation, especially putting greens. Download the NOAA National Weather Doppler app to ensure that you save yourself and your team the hassle of placing infill into wet turf.

I have three weather apps on my phone, and they are one of the best tools in my toolbox.

Placing infill when synthetic turf fibers are wet creates issues that will cause failure within your entire installation. Below are just a few.

- Prevents Ballast – The infill will stick to the fibers, preventing them from dropping to the base of the turf and ballast (weigh down) the turf system. Ballasts give stability and longevity to synthetic turf systems.

- Trapping of fibers – If the fibers are wet, the infill will bunch up and trap fibers causing large sand pockets.

- Voids – When synthetic turf is wet, infill will not drop evenly to the bottom of the turf system and will create voids in the system, which may cause premature wear and/or matting.

- Wrinkling – When the correct infill amount, weight and levels are not successfully placed, the synthetic turf may wrinkle in warmer climates.

- Matting – Matting will occur if infill amount, weight and levels are not respected.

What do I do if it has rained and the putting green surface is wet?

If you must get the job done due to time constraints and/or installation deadlines, you must dry out the turf for the infill to penetrate to the bottom. I recommend using a high-powered (backpack) leaf blower and drying out the entire surface prior to placing the infill.

Yes, this can be time-consuming, so learn your lesson and don’t do it again. Once the turf is dry, then proceed to infill.

Installing synthetic turf infill during precipitation will cause infill depths to be different than the synthetic turf manufacture infill specification. Infill depths that are not respected may cause a void in warranties.

If the required amounts of infill are not achieved, injuries or accidents may occur in systems requiring H.I.C (Head Injury Criteria), GMAX and surfaces rated for sports and training surfaces.

You will fail your project, and your project will fail you if you don’t pay attention to the details of infill placement. Investing in a good drop spreader will prevent these issues and create beautiful installations.

For more information regarding Drop Spreaders or need training, please contact J.W. at askjw@sgwcorp.com or call 888.846.3598.

Suggestions for the use of Ask JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither Ask JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.