Let’s face it — the water that we use today is very hard, which leaves deposits on everything. Synthetic turf also sees its fair share of hard water deposits. When hard water leaves deposits on synthetic turf, it looks horrible and can be frustrating to remove. This month, Ask JW will speak about hard water deposits, how to remove them, and how to prevent them from ruining your synthetic turf.

Hard water is formed when water passes through limestone deposits made up of calcium, magnesium, bicarbonates, and sulfates. You may witness hard water more in areas that are high in mineral content due to groundwater streaming through limestone. When hard water gets on surfaces, it is very hard to remove. Even the best sealers, paint, and car wax become the culprit of its leftover residue. When hard water deposits build up over time, they become thicker in height and require multiple cleanings to remove, especially when the sun’s UV rays bake it in.

Hard water deposits appear as a chalky white residue. This buildup of excess minerals, when left behind, may wreak havoc on many surfaces. Not only are these stains hard to remove, but they can destroy certain finishes when trying to remove them.

Overspray

Overspray is the most common cause for hard water deposits staining synthetic turf. Synthetic turf adjacent to landscape sprinklers will almost always get wet. Depending on how hard the water is, deposits will start to form on the turf fibers. Over time, these deposits will build up, becoming more visible and more difficult to remove.

Recognizing Stains During the Estimate

I have received many calls from contractors and homeowners stating that the turf stained the concrete. Synthetic turf does NOT stain concrete, pavers, flagstone, travertine, or other hardscape surfaces. It is unfortunate that clients never notice edges of hardscape staining with natural grass, but they will readily blame the synthetic turf. You must point out all existing stains that are present on the hardscape before contracting the project. This will ensure that you do not get blamed after the installation is complete.

I have seen newly-placed travertine stains within weeks due to hard water calcium buildup. If the hardscape surface is not sloped correctly, water may sit and absorb through the edges of concrete, pavers, flagstone, travertine, or other hardscape surfaces. When this happens, the area may experience staining along with efflorescence, alkali, and sulfate reactions. Many do not recognize it until plush green synthetic turf is placed against it.

Efflorescence, Alkali, and Sulfate Attack

Efflorescence is a white, powdery substance that occurs on the surface of concrete and hardscaping. It can happen within days, or it can take some time to form. Efflorescence is caused when evaporating water leaves salt deposits behind on the masonry’s surface. Over time, this can form a coating and deteriorate the substrate, becoming very unattractive.

Sulfate attack is another common form of concrete deterioration. It occurs when concrete comes in contact with water containing sulfates.

Be aware of all hardscaping when it comes to efflorescence and sulfate attack. If this is a pre-existing condition, it is crucial that the client acknowledge this before the start of the project. I have witnessed contractors get the blame for this, which is absurd.

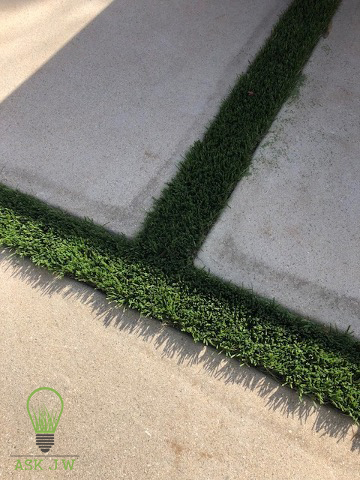

Turf Ribbons & Hard Water Buildup

When installing turf ribbons, the area must have an optimum slope. When water is allowed to sit, it will stain. When hard water is present, it will stain even darker. When there is sulfate present within the soil, it may start the eroding process. It is crucial to understand what this can do to an installation. This is where you might be blamed by the client for this condition. I have had many experiences with this same situation where the client never noticed this before placing the turf, and the installer was blamed.

Water Deposits & Texturized PG/Bocce

Hard water stains on sports surfaces, especially texturized putting greens, can look horrible and wreak havoc on how they perform. When calcium deposits build up, they become very hard. If you allow this to be present on your putting green’s surface, it will cause irregular ball roll. It is also very hard to remove if you allow it to build up over time. If you are designing a putting green for a client, make sure all irrigation and water run-off does not reach its surface.

Bocce ball courts should never be constructed near irrigation/sprinklers.

If you are planning to install “T-Line” synthetic turf at golf courses, you must take into consideration the damage hard water can do to its surface. T-Line is created to hold a golf tee while providing practice to the golfer when hitting or driving the golf ball. If the surface becomes contaminated with calcium build-up, it makes it difficult for the golfer to simulate natural play. I recommend either constructing a collar of hardscape around the T-Line to prevent water/irrigation overspray from hitting the surface, or maintain and clean the area often.

“It is your client’s choice… do not make it yours”.

Water Deposit Removal

There are many ways to remove hard water and calcium deposits. Depending on the surface, it may take multiple cleanings to remove it completely. As I mentioned above, hard water deposits build up over time and become thicker in height. They may require multiple cleanings to remove, especially when the sun’s UV rays bake it in. I view hard water deposits like a cracker. At the beginning stages, it can be easy to remove since it may be the first fine layer. When this is allowed to happen continuously, however, the deposits will build up over time like stacking crackers on each other. This is important to understand because it will assist you in removing. Depending on how long and how thick the deposits are, removal may take some time and patience. When you use cleaning agents along with the water, it will saturate the deposit and layers can be removed at a time unless you have machines assisting you. I do not recommend high pressure or aggressive scrubbing machines for removal; this may damage the turf fibers. Allow each cleaning to dry. This is crucial in removing the next layer. If the area is still damp, the chemicals you use will not be able to penetrate it due to it being wet.

Vinegar

There are many products on the market that combat calcium buildup. Vinegar and water have always been an all-time favorite when removing hard water spots. Depending on how it is diluted, it can do the trick in removing spots from all types of surfaces. One must be careful when using vinegar, especially around pets. Dogs have a remarkable sense of smell that is very different from humans, and vinegar drives them away. Vinegar has often been used as a deterrent to keep animals at bay. I would not recommend vinegar on your synthetic turf.

CLR

CLR is another household favorite. CLR works great for texturized putting greens when they succumb to hard water deposits. Make sure you clean the entire putting green surface so that the overall color will blend.

Hydrogen Peroxide

Over the counter hydrogen peroxide is also known to combat water stains and soap scum. It works great around the home, and it even eliminates fungus around the garden.

Safety should always be the #1 priority when using any type of cleaner. Gloves, glasses, goggles, and or/face shields must be worn. I recommend following the cleaner’s safety instructions while using it. It is crucial to clean the synthetic turf either early in the morning or late in the evening when the temperature drops. When it is hot outside, the heat will cause cleaners and water to evaporate before they can do their job.

Water stains are no fun, especially when they cause your turf to turn white. If you keep the hard water from reaching your turf, you will not have to take these steps to remove buildup. If you have issues removing hard water stains from your synthetic turf, or if you have any questions, you can always turn to me for answers.

For more information regarding cutting around playground poles or would like to schedule a training or webinar, please contact J.W.: askjw@sgwcorp.com or call 888.846.3598

Suggestions for the use of ASK JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither ASK JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.