Infill plays a major role for the longevity of synthetic turf. Decades ago, many turf contractors used all types of raw materials to place between turf fibers. Some would tell you that Infill is placed to protect the backing from the sun’s harmful rays. Some would say it was used mainly for the purpose of keeping the fibers erect and prevention of matting. Many would argue the fact that it was used to simulate “natural soil” for drainage and permeation. All the above are facts and are all true.

This month Ask JW will explain the Importance of “Infill Maintenance”, its many uses, and how crucial it is to keep levels maintained throughout the warranty period.

The Main Cause Behind Synthetic Turf Wrinkles?

- Improper Ballast

- Improper Ballast

- Improper Ballast

- Improper Ballast

“Ballast” is defined as a heavy material used to improve stability and maintain balance and steadiness.

When Installing synthetic turf in the heat of the day you will be fighting “Thermal Contraction & Expansion”, which may cause wrinkles prior to placing Infill. Placing a boat load of nails everywhere you see a wrinkle will only lead to frustration and a steel shortage.

If you have an installation that will require multiple days to complete, I recommend scheduling the placement of the Infill to be early in the morning or early evening. Thermal expansion/contraction occurs when temperatures rise and lower.

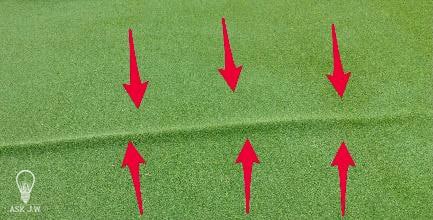

Maintenance & Ballast

Maintaining Infill levels are important in keeping synthetic turf secure, stable, and flat to the planular surface that is created. Infill is used to “weight-down” the turf to prevent movement. When synthetic turf is lacking specified amounts of Infill, expansion and contraction will occur. When extreme heat is present, synthetic turf that is “Infill deficient” will lift and pull from weakest point/areas. Theses weak point/areas that lift, create wrinkles. The volume of “Infill deficiency” will determine the amount, size, and length of the wrinkles.

During Installation when the temperatures are cooler the wrinkles are less to appear. When the temperature rises, the heat transfers within the turf and causes the backing to swell and lift from the ground. Some synthetic turf when wrinkled is stronger than the 2lbs. of infill you are trying to use to flatten it. I recommend purchasing an Infill “Depth Meter” to ensure your Infill depths are at proper levels.

Granular Size

Infill granular size and weight is very important for ballast. Educate your team about different infill types, sizes, and placement. Avoid using materials like beach sand, coal slag, dirty silica, fine cement sand. Maintaining and utilizing the correct infill and amount, you can prolong warranties and prevent movement/wrinkling.

Raining, Flooding & Ballast

Rain, snow, sleet, and hail can deplete infill levels on all types of synthetic turf. When continual flooding happens, Infill levels will need to be measured and replenished. If the infill levels are not replenished during hot summer months, the turf may move and wrinkle.

Putting Greens & Ballast

Whether you are installing texturized or slit-film turf, it is critical to understand what it takes to “ballast” the product as well as “negative thermal expansion’s” role for a successful putting green installation. “Negative thermal expansion” is defined as the tendency of matter to change in volume in response to a change in temperature through heat transfer. If you do not “Ballast” putting green surfaces they will move on you. If you are using putting greens for monthly practice, I recommend maintaining your putting green surface monthly. I also recommend replenishing and rolling putting greens in the spring after snow fall and/or winter conditions.

Texturized Putting Green

A typical texturized synthetic turf putting green averages around ½ inch in thickness and requires between two and four pounds of infill per square foot.

I recommend using #60mesh size granular infill that will quickly drop to the base of your putting green surface. This infill will not only minimize the need to aggressively scrub, but it will also save your installers time and labor to complete the infill process. Infill levels must be maintained on texturized putting green materials or damage may occur along with movement and wrinkles.

True Putt (Slit Film) Putting Green

“True Putt” product is an exception to your typical putting green as it is a tournament quality putting green surface and features high Stimp meter speeds. This product acts much like real bent grass and requires four to six pounds of infill per square foot. If the Infill becomes depleted, the Ture Putt may need to be defibrillated and Infill replenished.

Playground Surfaces & Ballast

Every playground system needs Infill maintenance. When heavy traffic areas start to lay flat or matting occurs, I recommend revitlaizing the playing surface by defibrilation then replenishing the specified Infill. I recommend placing a “Micro-Ancrobial” Infill for all synthetic turf areas where blood, urine, and vomit is a concern.

Sports Fields & Ballast

Most synthetic turf sports systems are created to allow rapid flow of water through drainage holes and into the underlying drainage system. Water/fluids must pass through the system. Infilled synthetic turf is not accommodating to large amounts of drainage by surface runoff. When synthetic turf and the underlying drainage system become inundated with water this can displace the Infill. Crumb rubber is buoyant. Storms that produce heavy rainfall in a short period of time cause the infill to migrate to lower lying areas. Having a positive planular “longitudinal ridge” allows excessive run-off to the left and right of the longitudinal crown. If the Infill becomes deficient, it is crucial to immediately replenish the specified Infill or it may cause movement in the synthetic turf surface. Maintenance of “Ballast” is a crucial element for keeping sports surfaces safe. When Infill levels synthetic turf sports fields become low, Gmax and H.I.C. testing may fail. Heavy rainfall can result in “Trapped Air” below the synthetic turf surface causing “Air-Locking”. When this is coupled by “lack of ballast”, it will allow the turf to lift and leave behind wrinkles. Having clogged perforations along with contaminated geotextile may cause build-up of air pressure as well. When “Air-locking” occurs, this may cause the synthetic turf to “bubble” and lift resulting in wrinkling of the turf.

The STC requires routine grooming after every 80 hours of use, or a minimum of once per month. Additional grooming may be necessary based on frequency or intensity of usage

When synthetic turf is placed over Airdrain Drainage Grid, ballast is crucial. Airdrain cannot be nailed or stapled when placed over concrete, asphalt, and rooftops other than securing to a nailerboard. When synthetic turf Is placed on top of Airdrain Grid and is “Infill Deficient, you will get movement and wrinkles. Rooftops must rely on maintaining the weight from “Infill ballast” to prevent “Wind-Lift”.

Pet Turf & Ballast

Micro-ancrobial Infill is the latest technology in infill product for synthetic grass. Animal Urine, blood, vomit, and other external elements are not absorbed into Micro-ancrobial Infill which eliminates the building of bacterial spores within the infill product. When Micro-Ancrobial Infill levels are depleted, the turf will move and begin to smell. It is important to have a maintenance program in place to prevent this from happening.

Zeolite Infill along with enzymes are the #1 choice for pet turf odor control. Keep in mind, Zeolite is not made to withstand heavy traffic to keep fibers in a vertical state. The granular structure resembles a “honeycomb” appearance and does not constitute a stable granular to be installed as a complete infill.

Infill provides stability for synthetic turf. Zeolite is not heavy enough to be used as a primary Infill. Zeolite is primarily used as an added infill or “Top-Dressing”. When Zeolite is wet, it absorbs up to 81% of its original weight in water and 55% of its weight in urine. However, once the granule dries out, it returns to its original state and is not heavy enough to keep the synthetic turf ballast, which may allow wrinkles in the turf. Because Zeolite becomes softer after it absorbs liquids, it is not a good candidate to be used as a 100% infill for synthetic turf. The Mohs scale of mineral hardness characterizes a mineral’s scratch resistance through mineral’s ability to scratch a softer material.

Below I have provided you each infill’s measurements on this scale for comparison.

- ZeoFill: 2-4

- Silica Sand: 6-7

- Coated Silica (acrylic, urethane) 7-9

If your project requires “odor control”, I recommend maintaining the top dressing monthly, depending on the amount of use and the quantity of pets.

When synthetic turf ages, maintaining and replenishing infill levels may become a tough task to do. I always speak about “static electricity”. Be mindful of “static electricity” while incorporating and maintaining your infill. When using a substandard infill and infill size, the installer must aggressively scrub the infill with either a push broom or fibrillating machines to work the infill below the surface. The excessive scrubbing creates static electricity and causes most infill to stick to the fibers.

How Much Will I Need?

“Maintaining Infill Ballast Is the most effective way to control thermal contraction and expansion in synthetic turf. If a sizable section of turf is not provided with proper amounts of infill to accommodate temperature movement, the synthetic turf will be allowed to move excessively which may cause wrinkling, seam rupture and/or splitting of the synthetic turf backing. For more information regarding Infill maintenance, ballast, or wrinkling, give me a shout”!

888.846.3598 or email AskJW@SGWcorp.com

Suggestions for the use of ASK JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither ASK JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.