Being a veteran of the synthetic turf industry, I have witnessed the “end of life” on thousands of installations that lived past their warranty. I have also seen new installations prematurely deteriorate the same year they were installed. Much of the deterioration was a result of excessive friction. I have expressed my concerns about wear and tear in high traffic areas in many of my columns and thought it would be advantageous to dive deeper into installing traffic mats.

This month, ASK JW will teach how excessive friction can destroy your installations and what can be done to prevent this and get more life out of your playground surface.

Let’s face it; playgrounds take a beating. It does not matter what surface you place or how small the children are; continuous foot traffic takes a toll on playgrounds. Poured-in-place rubber has been a choice for playground surfaces throughout the years, but the yearly expenses to patch and re-seal can add costs that will never go away. For decades, I have witnessed playgrounds in bad shape where city officials shut them down due to finances. Repairs were never made, which caused further damage to the playing surface. Existing poured-in-place rubber playgrounds across the nation have been remodeling their surfaces by installing synthetic turf.

Synthethic Turf Playgrounds

I have been extremely fortunate to have advocated, designed, evaluated, trained, tested and remodeled hundreds of playgrounds with synthetic turf. Synthetic turf playgrounds have a system that includes nailerboard, drainage rock, shock pad, synthetic turf and infill. I see too many contractors trying to get away with avoiding steps, including removing materials needed to complete the entire system. The whole system allows the surface to pass appropriate GMAX and H.I.C testing. It is crucial to understand critical fall height requirements when placing synthetic turf in and around playground equipment. It is also critical to understand wear and tear and where this occurs.

Quality Turf

All playground installations start with quality turf.

Does the synthetic turf you’ve chosen have what it takes to combat excessive friction?

Can the product you place withstand a beatdown?

Does your complete synthetic turf system have testing certifications, such as GMAX/H.I.C.?

I ask contractors these questions but never get a solid answer. Unfortunately, most hide behind the warranty of their turf.

Excessive Friction VS. Warranty

15-year warranty? Woo-Hoo! This is awesome, don’t you think? Most manufacturers warranty their turf against defects; unfortunately, damage by excessive friction is not one of them. Keep this in mind the next time you boast about how long a warranty you give.

If your playground is damaged with holes like the image to the left, it is a candidate for traffic mats. Be aware, damaged synthetic turf may cause injuries.

Workmanship

“There is never enough time to do the job right, but always enough time to do it over…

Don’t be one of those people.”

Excessive friction can cause damage, which may cause seam rupture and/or separation. Poor planning, materials and workmanship will always cause havoc on your installations, not to mention driving back to the job to fix something that should have never happened.

I recommend never laying synthetic turf where seams are under heavy foot traffic areas. This would include slides, swing sets, climbing features and play equipment exits. The underpadding/shock pad is flexible. If a seam is placed in these areas, it may eventually cause seam separation. You might have to figure waste in your budget to avoid having seams in these areas.

Friction/ Traffic Mats

Friction mats are sections of turf placed at all slides, swing sets, climbing features, and play equipment exits. Traffic mats are usually made up of nylon putting green materials. Nylon fibers are very aggressive and can withstand foot traffic better than regular landscape turf. Friction mats minimize the damage synthetic turf may receive over the years of condensed friction. A skilled installer can place traffic mats in a matter of no time. I recommend planning the location of friction mats at the beginning of the playground installation.

Staples

Having the proper tools, materials, and patience will allow you to create a friction mat that can last years.

If you have existing damage in high traffic areas, please follow the steps below in removing the damaged turf and replace with quality nylon putting green material. This material will perform much longer than a landscape turf repair.

1. Lay out the friction mat to cover the area large enough outside the friction wear area.

2. Use a chalk line and mark the desired size of the friction mat.

3. Vacuum out existing infill within the traffic matt location. This will allow for an easier cut and removal.

4. Take a sharp knife and cut a small slit at one corner of the marked lines. This will allow the mouth of the push-cutter tool to fit in.

6. Using the push-cutter, push-cut along the chalk line while cutting the section out. Remove the damaged section.

7. Clean the edges to ensure all infill and frayed turf fibers are removed.

8. Place SGW seaming tape and Superseam Pro 444 adhesive to unify the traffic mat to existing synthetic turf. Superseam Pro 444 adhesive is the strongest adhesive on the market today.

Placement of Infill

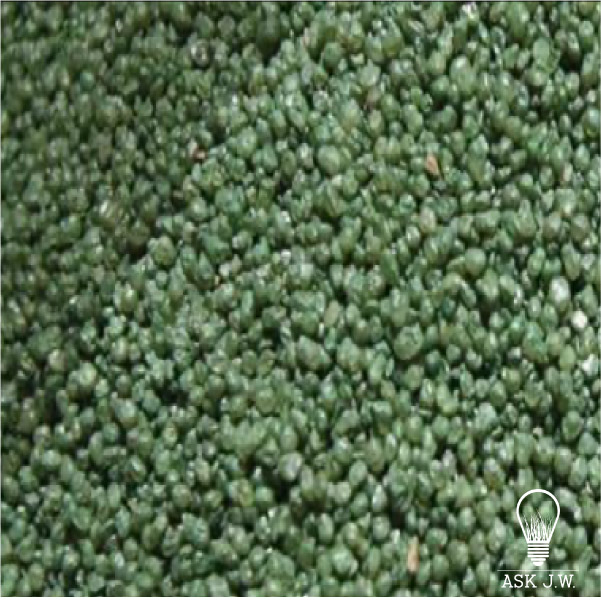

I recommend placing Envirofill Anti-Microbial Infill for all playground installations.

Envirofill eliminates the building of bacterial spores within the infill product.

Envirofill is round, which assists with movement and gives longevity to the system. Envirofill is environmentally safe and does not contain silica dust, zinc, or heavy metals. Envirofill combats the absorption of blood, vomit, animal urine, and other external elements.

Cutting

Every playground system needs maintenance. When heavy traffic areas start to lay flat and matting occurs, I recommend powerbrooming and placing additional infill to revitalize the playing surface.

For more information regarding cutting around playground poles or would like to schedule a training or webinar, please contact J.W.: askjw@sgwcorp.com or call 888.846.3598

Suggestions for the use of ASK JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither ASK JW nor SGW shall be liable for the outcome of any use of said materials, including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.