“Seam Rupture is the breaking or bursting of two sections of synthetic turf due to either improper installation, thermal contraction, wear or manipulation by physical force. Learning how to repair ruptured seams is not only important, but it will make you better at installing seams.” …JW

Terms to remember

Seam Rupture– The breaking or bursting of two sections of synthetic turf due to thermal contraction, wear or manipulation by physical force.

SGW Superseam Pro Adhesive– the Industry’s #1 Synthetic Turf Adhesive

Gauge: an outline of rows of tufted fibers stitched into the backing of synthetic turf rolls.

Synthetic Turf Mohawk– When two sections of synthetic turf are joined together, the fibers formed a ridge causing a visible line

Synthetic Turf Seam Integration: the action of forming two sections of synthetic turf together to unify as one.

Adhesive Seam Compression: pressure that is applied to seaming area of two sections of synthetic turf onto adhesive glue and seaming tape

Terms to remember

Seam Rupture– The breaking or bursting of two sections of synthetic turf due to thermal contraction, wear or manipulation by physical force.

SGW Superseam Pro Adhesive– the Industry’s #1 Synthetic Turf Adhesive

Gauge: an outline of rows of tufted fibers stitched into the backing of synthetic turf rolls.

Synthetic Turf Mohawk– When two sections of synthetic turf are joined together, the fibers formed a ridge causing a visible line

Synthetic Turf Seam Integration: the action of forming two sections of synthetic turf together to unify as one.

Adhesive Seam Compression: pressure that is applied to seaming area of two sections of synthetic turf onto adhesive glue and seaming tape

Step 1.

When repairing a seam it is very important to remove all the infill before the repair is going to be made. I recommend using a shopvac or a high-performance blower to either remove or blowout the infill. It is very important to remove the infill past the repair so that a buildup of infill is not left behind causing a ridge which can be very hard to level out.

Step 2.

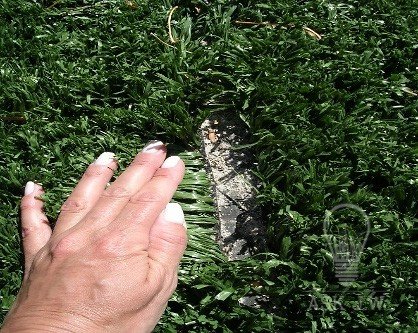

If the seam has pulled apart, take a carpet kicker, place it a minimum of two feet away from seam and kick the two sections together to the width of the manufacturers gauge specifications. Seams that are kicked too close together will create a “mohawk” and will be visible after the infill process.

Step 3.

You may have to trim the seams edges to fit.

Step 4.

When the seam is placed together, and to its required gauge width, I recommend placing temporary nails approximately 18 inches from the center of the seam on both sections. This will allow the turf not to move during the gluing process.

Step 5.

When repairing a seam rupture that was installed with seam tape you must remove any existing seam tape and replace with new seam tape. Place seam tape in the center of the two sections and secure with either staples or nails.

Step 6.

I recommend using SGW Superseam Adhesives when securing two sections of synthetic turf together. SGW Superseam Pro when applied correctly is guaranteed for the life of the seam.

Step 7.

Once the infill is removed, fold open and secure the two sections.

Prior to placing adhesive, take the shopvac or blower and clean out any excess infill that had dropped on the seam tape.

It is very important to place the adhesive at 1/8 inch on the seaming tape.

Step 8.

Ruptured seams that are minimal may require a helper to hold open while placing the adhesive.

Step 9.

Carefully connect the two sections together.

Step 10.

I recommend placing 50 pound infill bags for compression while the adhesive is curing. Check the seam every 15 minutes to ensure any excessive adhesive coming up through the center of the seam and/or drainage holes.

Step 11.

When the adhesive has cured, I recommend replacing the infill by hand. This will prevent trapping the fibers which will make the seam visible.

Step 12.

Seam ruptures that are really bad will either need the sections to be replaced entirely or newly placed strips of turf will be needed to be inserted to fill in the gap. (I will discuss this technique in next month’s column)

Synthetic putting greens that have seam rupture will need to be replaced entirely and installed properly.

Stayed tuned for next month’s Ask JW’s series on “Making Repairs in synthetic turf”

For more information contact J.W. askjw@sgwcorp.com or call 888.846.3598