Synthetic turf playground surfaces and installations have evolved over the last decade. Underpadding and shock pads that meet fall heights (H.I.C. head injury criteria) have improved and now have longer life spans than ever before. The foam Shock Pad absorbs impact reducing the risk of injury, protecting the children from falls. In a fantasy world, it would be nice to have the entire shock pad to be manufactured as one piece, but that is not the case. Unfortunately, installations have become the center of attention for “Shock Pad Failures”.

This month ASK JW will go in detail about how important factors when installing shock padding below synthetic turf.

SGW’s Underpad is made of 99% recycled, non-contaminated post-industrial cross-link closed cell polyethylene foam. The Underpad/shock pad should be installed directly under the turf to deliver additional shock absorbency to ensure children’s safety. The Underpad is made up of recycled materials and available in 3/4“, 1 1/8” and 2 1/8” cushions to meet or exceed fall-height and ADA requirements. Synthetic Grass Warehouse carries light, medium, and high-density foam for all playground and sports field applications

Underpadding/Shock Pad Failures

Over the years I have witnessed failures that have caused playgrounds to be shut down due to the safety concerns regarding underpadding issues. Many synthetic turf contractors are not installing Shock Pads properly. Simple installation procedures can prevent an entire project to be removed and replaced. Below are some important factors when installing Shock Pads.

Storage & Care

Do not expect your Shock Pad to install properly and maintain what it was designed for if you do not take care of its storage and job site stocking. If the Shock Pad becomes deformed due to its storage and stocking you may as well throw it away. Not only will you struggle with its installation, but it may not perform to its required safety criteria.

When Shock Pad is damaged, it will void its fall height requirements.

Expansion & Contraction

I recommend never leaving gaps between the panels when installing Shock Pads. Many believe that leaving 1/8 of an inch between panels for expansion will prevent the panels from curling when they expand. The padding will only expand when the ambient temperature is hot and direct sunlight is hitting the panels – this is normal. I recommend placing the shock pad early in the morning before it gets too hot. Make sure to have a big enough crew to help with installing the turf and immediately place in the infill for ballast. Once the infill has been properly placed, the entire system will have stability and thermal contraction/expansion will not affect its placement.

If you do not have the luxury to dodge the heat of the day, make sure you always place the infill for ballast early in the morning. The best time for placing infill is early in the morning when the temperatures are cool. This is when the Shock Pad and synthetic turf has settled to its flattened state and will allow easy placement of infill without wrinkles forming.

I have witnessed hundreds of failed Shock Pad installations and most of them were due to contractors leaving too large of gaps between each shock pad. It can just take a year of play to cause gaps to mirror through the surface of the turf and eventually lead to damage.

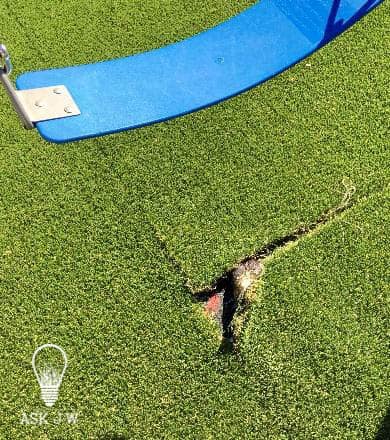

When this happens, the edges of the foam along with friction starts to cause separation of the backing, causing a “splitting fest”.

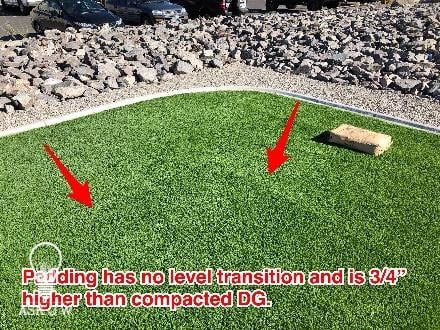

The project in the image above eventually will have damage at every gap opening and elevation difference that was left in the Shock Padding.

Shock Pad Transitions

When installing Shock Pads, you must have a proper transition. The images above show the Shock Pad placed several feet from the outside curbing. I DO NOT recommend doing this. Like I had mentioned above, this will eventually fail and cause the turf backing to dry out and split, due to the Shock Pad Edge being higher than the compacted subgrade.

When installing Shock Pads, you must have a proper transition. The images above show the Shock Pad placed several feet from the outside curbing. I DO NOT recommend doing this. Like I had mentioned above, this will eventually fail and cause the turf backing to dry out and split, due to the Shock Pad Edge being higher than the compacted subgrade.

All SGW shock pad has a 1/8” inch tolerance. If your shock pads are more than a ⅛” difference in thickness, then please contact your SGW Representative.

It is very important to always check the dimensions of the Shock Pad to make sure there are no discrepancies in thickness.

Placing a Shock Pad that has “inconsistency in thickness” may cause immediate damage to the turf system.

Installation of the Underpadding/Shock Pad

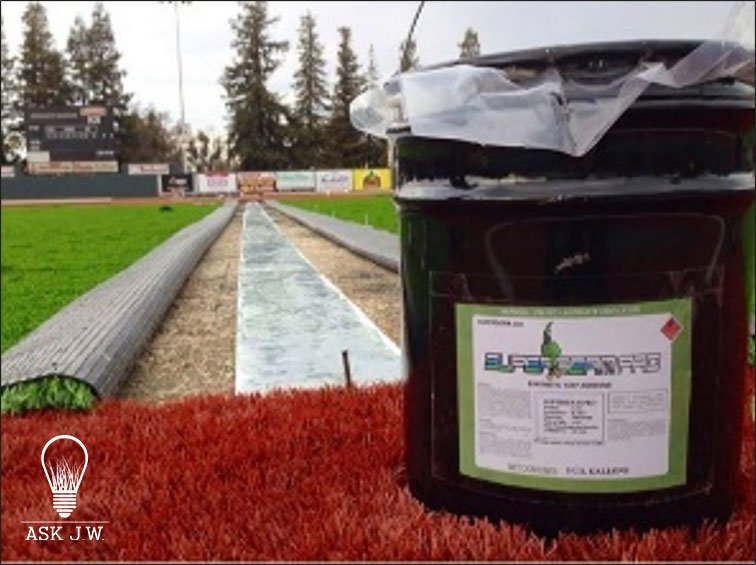

I recommend placing seam tape and adhesive to all connecting edges of the underpads/shock pads.

Separation of the underpadding due to thermal contraction and expansion in dry desert climates will cause the pad to sometimes heave. Heaving underpadding can cause turf seam separation. When the underpadding/shock pad is installed incorrectly the entire playground system will fail.

Seaming the underpadding sections together will give the entire playground stability and withstand heavy foot traffic without causing the underpadding to settle which is the start of synthetic turf splitting. (Notice the settlement of the foam padding in the picture to the left)

Lay Out & Placement of the Underpadding/Shock Pad

The Fabric Side of the Underpadding Should Be Face Up.

Place the underpadding/shock pad on top of the compacted materials in an offset pattern like the diagram shown above.

I recommend placing the shock pad approxamately ¼” above all exterior nailer board and hardscape. This will allow for compression due to heavy foot traffic and may prevent future trip hazards.

Trimming of the Underpadding/Shock Pad

Precisely trim around all playground equipment and edges. It is very important that you do not leave any gaps around playground equipment and edges.

Securing the Shock Pad

I recommend using seaming tape and Superseam Pro Adhesive to secure the underpadding/shock pad together. This will give the playground system stability during heavy use and prevent the shock pad from moving while installing the synthetic turf. Do not use more than a 6” seaming tape and adhesive. Larger widths of seaming tape and adhesive will lessen the flexibility of the underpadding. Place seaming tape at all seams and glue all sections together as you go so that you can keep the connections tight without having to go back and re-adjust.

Tips for Synthetic Turf Playgrounds

DO NOT lay out the synthetic turf where there are seams under heavy foot traffic areas. This would include slides, swing sets, climbing features, and play equipment exits. The underpadding/shock pad is flexible – if a seam is placed in these areas it will eventually cause seam separation. You might have to figure in your costs to have waste to avoid having seams in these areas.

I recommend placing dense nylon putting green material at all slides, swing sets, climbing features and play equipment exits. This will minimize the damage synthetic turf may receive over the years of heavy foot traffic.

The damage that is in the picture to the left could have been prevented by acknowledging and reinforcing the “wear areas”.

I have installed, maintained, and repaired thousands of square feet of all types of playground surfaces. A quality synthetic turf playground system combined with quality materials and a well-executed installation will last for years.

Ask JW

Stay tuned for next months “Ask J.W.” column

For more information or if you would like to speak to JW regarding other Turf questions, please feel free to call him at (888) 846 3598 or email askjw@sgwcorp.com