Synthetic Turf & Trench Compaction

Throughout my career in the synthetic turf industry, I have expressed how sub-base compaction can make or break your installations. This month, ASK JW will explain how trench compaction is crucial for stability, longevity, and beautification of a synthetic turf surface.

For synthetic turf to simulate natural grass, the surface must remain true to its shape, contouring, and smoothness. When excavating trenches in sub-base below synthetic turf surfaces, superior compaction is a must. Substandard compaction and excessive foot traffic may cause depressions and/or settlement. When this happens, removal and replacement may be the only choice.

Irrigation Trench Compaction

In my decades in the turf industry, I have witnessed hundreds of installations that have failed due to backfilling. Many contractors overlook details when placing and compacting materials in trenches, especially around utility boxes. Most depressions and settlements occur due to water intrusion. Over time, leaky valves erode soils, which cause utility boxes to tilt and settle. I recommend placing ¾” aggregate at full height around utility boxes. This will stabilize the utility boxes and allow water to penetrate and drain without eroding soils.

Please read my column, “Synthetic Turf & Utility Boxes,” to learn more.

Removing trees, plants, and shrubs without proper compaction will cause depressions. It is crucial to backfill all holes with aggregates that will permeate, stabilize, and prevent settlement.

Compaction & Cohesiveness

Soil is a combination of sand, gravel, silts, clay, water, and air. To ensure that compaction is successful, cohesiveness is needed. Choosing the correct materials is crucial to trench compaction. Many contractors place existing trench soils back into the trench. This may work if the existing soils are compactible and free of contaminants. Existing soils present after removing natural grass may be too soft to use for backfilling. The soil must be compressible without allowing water intrusion to weaken its structure, even after it has been machine compacted.

Soils high in clay may not be a good candidate for trench compaction under synthetic turf. This is due to the reaction between these types of soils and excess water that may be present or at heavy rainfall. When contaminated soils become saturated, they tend to expand and settle, especially in narrow trenches. Narrow trenches backfilled with inferior soils may experience depressions and settlement due to heavy foot traffic.

It only takes one heavy rainfall to cause erosion of smaller fines in the trench, which may cause settlement.

Pea-Gravel has been used for backfilling due to being self-compacting. I believe this to be a myth and disagree to an extent. If your trench is two or three feet deep and you are topping the last foot or so with road base, then Pea-Gravel may work in this situation. However, we are talking landscape irrigation trenches averaging 3” to 12” wide and about 12” deep.

I recommend placing and compacting ¾” limestone aggregate as a backfill material for trenches under synthetic turf. Limestone rock is clean, slow absorbing, and creates a structure that will allow excess water to filter through, preventing shrinkage and settlement. If you live in an area where limestone aggregate is not available, please give me a shout, and I will assist you with a substitute for your backfilling: 888-846-3598.

Compaction Equipment

Having the proper compaction equipment is crucial for preventing trench settlement. There are different types of compaction equipment for purchase or rental. Plate compactors will not work well for trench compaction. Depending on the width of the trench, I recommend using a jumping jack or bench sand hammer (image to the far right).

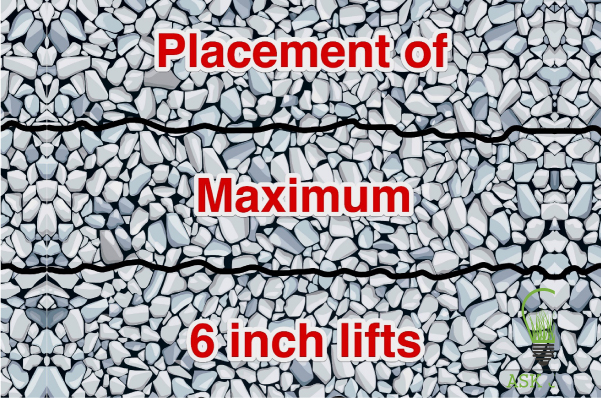

Backfilling & Lifts

It is crucial to place imported materials in lifts. Lifts are the thickness and amounts of materials placed at once. Placing too much at once will not achieve density. The size of the compactor machine will also determine the thickness/amount of lifts. I recommend using 6-inch lifts maximum, along with a jumping jack compactor or equal.

This will ensure that the trench is properly compacted and will not have any future settlement.

For more information regarding trench compaction or if you would like to schedule a training or webinar, please contact J.W. at askjw@sgwcorp.com or call 888.846.3598.

Suggestions for the use of Ask JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither Ask JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.