Throughout my decades of being in this industry, I have witnessed some crazy tools being used to apply turf adhesives. I have seen drywall spatulas, cardboard, turf scraps, folded seaming tape, and, yes, a paper cup. Using an improper tool to apply the adhesive will cause the seam to fail. During my travels and training, I have asked turf installers if they were familiar with the turf adhesives they were using, and many of them had no idea how crucial the application rate and thickness can be. Most of them admitted that they have never read labels on their turf adhesive, nor researched how the adhesive even works.

This month, Ask JW will stress the importance of adhesive thickness and how using the improper application tool will wreak havoc on your turf installations.

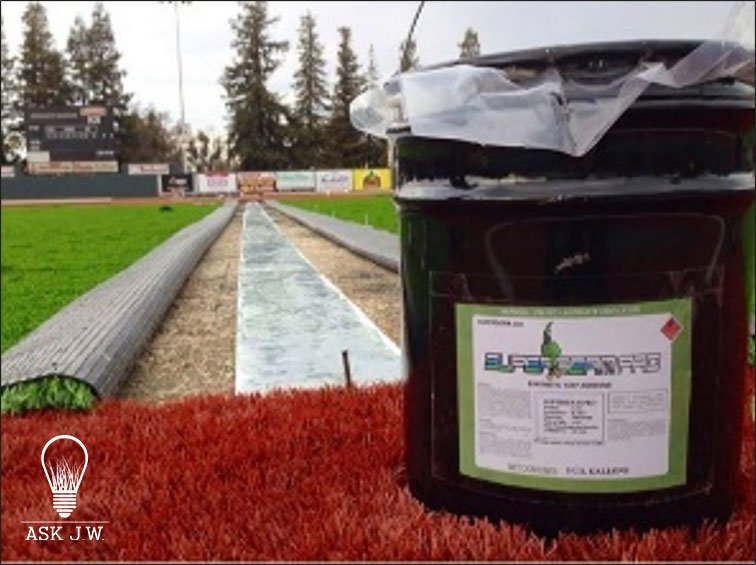

Synthetic turf adhesive lays beneath the turf backing, exposed to harsh weather conditions, excessive moisture, and thermal contraction and expansion. To ensure that multiple sections that have been seamed together stay together, a superior seam adhesive must be used. Superseam Adhesives have taken on that challenge for decades and have proven to be the best in the industry.

Superseam Adhesives are “moisture cured urethanes” and are made up of a blend of polyurethanes/prepolymer. Superseam Adhesives work by means of chemical and mechanical bond rather than just a mechanical bond. They chemically “attach” themselves to the surface as well as “grabbing” and “locking” onto the substrate. Superseam Adhesives’ mechanical properties include elongation, compressibility, tensile strength, elasticity, tear resistance, and fatigue resistance. When unifying two sections of synthetic turf, the seam could move considerably, requiring the adhesive to expand and contract significantly without losing adhesion from the seam tape and backing of the turf. Temperature, rate of temperature change, and how the adhesive was applied will all influence the results.

“It’s More Than Just Spreading Glue” … JW

The front man in this photo has the correct tool and is placing the adhesive with a notched trowel at the specified thickness. The second man is flattening out the adhesive with a drywall knife, reducing its thickness. This is bad because it may prevent the adhesive from reaching between the gauges on the backing of the turf.

Optimum performance is when the synthetic turf adhesive is applied with the correct tool, at the correct thickness, with even compression throughout the curing process.

“Too Much is Too Much…Not Enough is Not Enough”

All adhesives on the market today have specifications that require a certain width and thickness of how much adhesive is to be applied to the surface. When the adhesive is placed too thick, you will end up like the images above. These projects had to be removed and replaced due to user error. Too much seam adhesive can affect the seam and its fibers’ integrity. Placing the adhesive in the hot summer months can cause the adhesive to expand, foam, and seep up through the seam line, sticking to the fibers and making the seam visible. Using moisture cure adhesives that creates excess foaming properties may also cause seam failures. I recommend NOT using these. Excess foaming causes the seam to lift, creating noticeable seams. I recommend using Superseam Adhesives, which does not foam and can be used in extreme weather conditions.

This installer not only placed too much adhesive but spaced the bags for compression too far apart. When you leave gaps between the objects that you are using for compression, you allow the adhesive to expand and cure in these areas that have no pressure on them. This will leave behind little speed bumps.

I recommend placing the bags tightly together to prevent what happened to this installer.

Clearly this installer did not place the correct amount of adhesive. It was placed so thin that the stitch rows are clean as a whistle which allowed the seam to experience seam rupture.

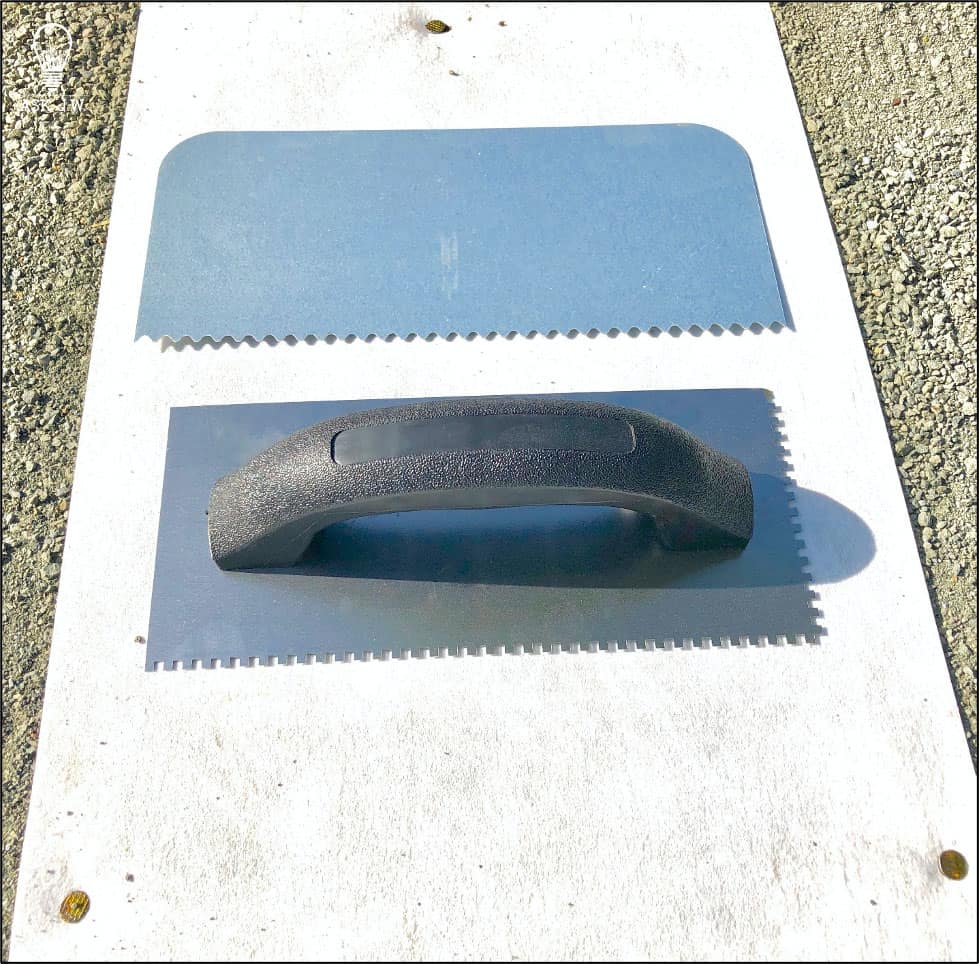

Application Tools

This is where many you head straight to the job and forget the most crucial item you did not account for when ordering your materials… the specified notched trowel.

Do not open that bucket of glue until you have the correct tools on hand. If you do not have a notched trowel, go get one. Home Depot sells the notched trowel pictured to the left for $4.99.

Don’t you think that is much cheaper than what is going on in the picture to the right? This installer had to replace the entire project due to the placement of adhesive. It’s only $4.99, peeps. Please get yourself several to have on hand so when that bucket of glue opens, you will be ready.

Fail to Plan… Plan to Fail

To have a successful seam installation, having the correct adhesive tools is crucial. Like I mentioned above, there is a lot more to seaming turf than slapping some glue on seaming tape. Below are some bullet points that I recommend that will assist you in perfecting your seam installations.

- Think safety.

- Check the weather and make sure there is not any rain in the forecast.

- Have all materials on the jobsite and ready to use.

- Store all Superseam Adhesives in a cool, dry place until ready to use.

- Have plenty of help when installing seams.

- Have the proper trowels to apply the adhesive.

- Have a “Spill Plan”. Murphy’s Law … It will happen.

- Double & triple check the seam prior to placing adhesive. Most seams will move with the changes in temperature. I have had many times that the seam had to be kicked together due to the extreme heat that rushed upon us, while in the gluing process.

- Get all the compression bags lined up tight with one another down the seam line.

- Place all adhesive pails and buckets on a protective tarp or cut a 2’x2’ piece of turf to place the adhesive on while not using.

- ALWAYS CLOSE AND COVER THE ADHESIVE CONTAINER. If there is any moisture or humidity, it will cause a layer of adhesive to cure inside the container.

- Place the adhesive on the seaming tape as quickly as possible. The faster you get the two sections of turf down on top of the adhesive, the better strength you will achieve.

- Knock down any excessive glue that was troweled more than the required depth. Anything over the specified thickness may cause issues.

- ALWAYS do a bag check every ten minutes to ensure there is not excess glue seeping up through the seam or drainage holes. This means pulling up chosen bags to check seeping.

- USE THE CORRECT APPLICATION TOOL & THICKNESS!!!

- USE THE CORRECT APPLICATION TOOL & THICKNESS!!!

- USE THE CORRECT APPLICATION TOOL & THICKNESS!!!

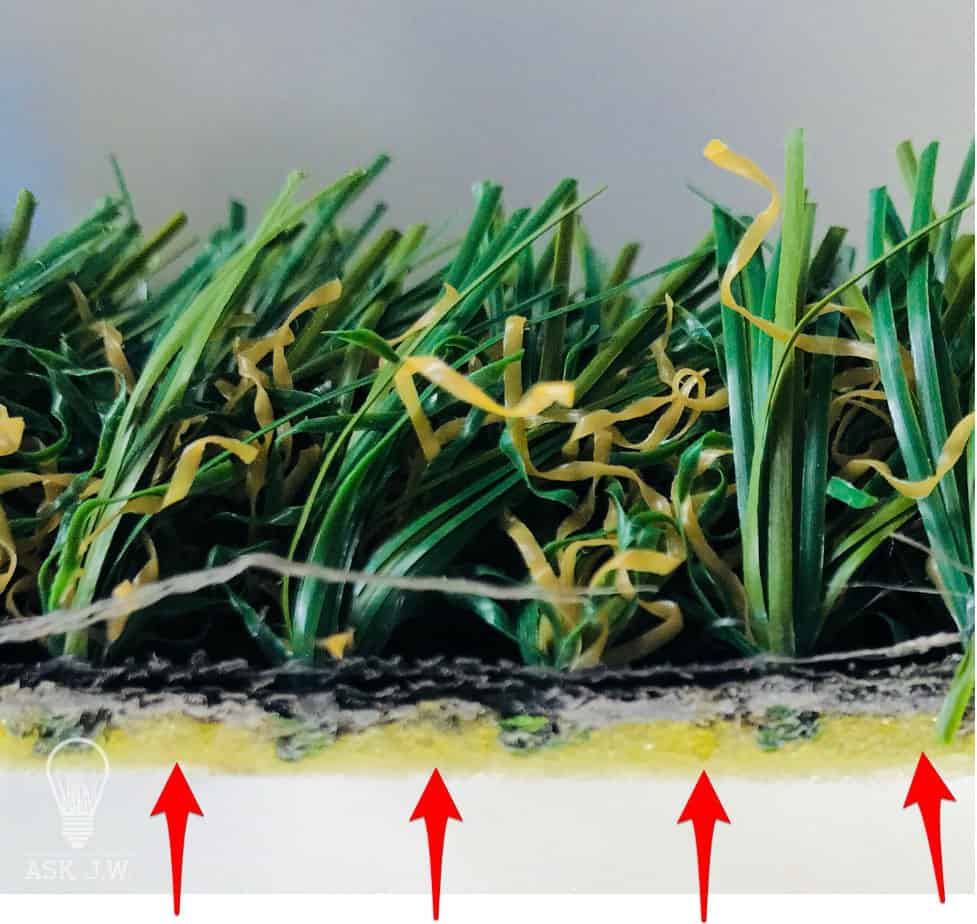

Successful Adhesive Placement

The pictures above show Superseam Adhesive Pro 444 applied by a synthetic turf craftsman at the correct depth with proper compression. The center picture shows a close-up cut view of how compression forced the adhesive up between the stitch rows/gauges/backing. Compression prevents voids and air pockets from occurring between the seaming tape to the backing of the turf. When this is accomplished, longevity is produced.

What does it mean to be a craftsman of installing synthetic turf? It means you must hone your craft for all the materials that go into the installation. When you become a craftsman in adhesive placement, you will see better results in your seam installations and have less “go-backs”.

I look forward to seeing you next month where I will be talking about our new synthetic turf disinfectant/cleaner. It is the only EPA-registered synthetic turf disinfectant and cleaner on the market today.

For more information regarding adhesive placement/adhesive issues or to schedule a training please contact J.W. at 888.846.3598 or email AskJW@SGWcorp.com

Suggestions for the use of ASK JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither ASK JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.