I was speaking to a contractor recently and he was telling me how difficult it was for his installers to install synthetic turf in cold temperatures. He said the turf rolled out stiff and was hard to cut which slowed down his installations. He went on to say that during the hot summer months his crew can cut in a job much faster because the synthetic turf was easier to stretch, but received “call backs” due to the turf moving causing wrinkles. I gave him a link to one of my previous columns, “Why is my turf wrinkling”, and then went on to explain about Thermal expansion and contraction.

Synthetic turf expands and contracts when subjected to changes in temperature. Most materials expand when they are heated, and contract when they are cooled. The expansion and contraction of synthetic turf is not a bad thing. Having flexibility gives longevity to synthetic turf systems. It is up to the end user to keep it maintained while going through the cycles of the seasons.

Just like concrete, synthetic turf expands slightly as temperature rises and contracts as temperature falls.

Even though synthetic turf is flexible and withstand

harsh environmental conditions, it may also move, crack, split and cause ruptures. Thermal expansion and contraction of synthetic turf varies primarily due to quality of materials, poor installation, immediate temperature range, age of turf, and ambient relative humidity. Of these factors, the quality of materials has the greatest influence on the expansion and contraction of synthetic turf.

This month Ask JW will go in depth about thermal expansion, what to look for and how to prevent future damage to your synthetic turf.

Terms to Remember

Sunlight Thermal Radiation – Is part of thermal radiation generated by the hot plasma of the sun.

Thermal Contraction – is defined as the tendency of matter to change in shape, area and volume in response to a change in temperature through heat transfer. It is the opposite of thermal expansion. When the temperature drops, atoms calm down and shrink. They aren’t bouncing so aggressively off of each other and don’t need that much space to coexist. When they shrink, the boundaries of the material shrink. The material contracts. Most solids, liquids and gasses contract when they are cooled.

Ballast – is defined as a heavy material used to improve stability and maintain balance and steadiness. In the turf world, the term Ballast is used to “Weigh down the turf, prevent wrinkling and give the entire turf system stability and longevity. Properly placing infill assists the turf fibers in maintaining vertical position.

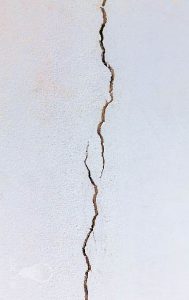

Seam Separation – Separation of two sections of synthetic turf that are seamed together.

Seam Rupture– The breaking or bursting of two sections of synthetic turf due to thermal contraction, wear or manipulation by physical force.

Gauge: an outline of rows of tufted fibers stitched into the backing of synthetic turf rolls.

Adhesive Seam Compression: pressure that is applied to seaming area of two sections of synthetic turf onto adhesive glue and seaming tape

Thermal expansion and contraction due to climate change can accelerate breakdown and degradation in synthetic turf. Most manufacturers today carry 10 to 15 year warranties for their turf products. Early stages of fiber wear and/or deterioration of the system is mainly due to poor quality of materials and/or installation.

The stress that thermal movement can cause to synthetic turf can be quick and damaging. UV Sunlight gives off thermal radiation generated by the hot plasma of the sun and will cause synthetic turf to wrinkle.

These wrinkles are created when the synthetic turf is exposed to extreme heat. The turf becomes hot and starts to pull from the middle uplifting, creating a wrinkle. Seams that are of poor quality will tend to shrink and pull apart from section to section causing seam ruptures. When a seam rupture is exposed to UV sunlight for long periods of time, the edge of the seam dries out, shrinks and starts the delamination process of the backing materials.

Synthetic turf seam ruptures not only can be ugly, but they get worse over time. The longer you wait to repair a seam rupture the more repairs you will have to make. In time, the open seam will start to deteriorate from its edge and work its way into the remaining synthetic turf.

Most Effective Way to Control Thermal Movement From Damaging Your Installations?

- Purchase quality materials – Purchasing low quality turf will set yourself up for failure. Not only will the turf fail, your business will eventually fail too. Don’t shortcut quality to save a few bucks. Synthetic turf that is of low quality may not even reach its warranty period when dealing with the harsh environmental conditions.

- Ballast – Is the most effective way to control thermal contraction and expansion. If a sizable section of turf is not provided with proper amounts of infill to accommodate temperature movement, the synthetic turf will be allowed to move excessively which may cause wrinkling, seam rupture and/or splitting of the synthetic turf backing.

- Securing of seams – When synthetic turf is faced with extreme temperatures, the two connecting points between multiple sections is usually the first to experience separating. Seaming two sections of synthetic turf is very critical in combating thermal expansion and/or contraction. I recommend using a quality seaming tape and adhesive when seaming two section together. The amounts of strength thermal contraction and expansion can have over synthetic turf can be astonishing. I have witnessed sections pull apart up to 4” inches. Applying adhesives improperly can allow movement of the seams due to not enough adhesive or compress when installing the seam. If the adhesive only touches the “stitch rows” and doesn’t bond to the “backing” too, you may experience premature seam rupture due to thermal contraction and expansion.

- Inspection & Maintenance – Inspecting the installation throughout the warranty period will prevent future damages, separations and seam failures. I recommend inspecting the installation every season to ensure that the infill depths are at the manufactures specifications, repairs are made and the area is kept clean of any debris.

Mistaking Poor Workmanship & Thermal Expansion and Contraction

Mistakenly cutting fibers at the edge of a seam may look like seam rupture until you inspect the seam closely.

Improper seam tape will allow thermal expansion and contraction to cause the seam to rupture. If the seaming tape and/or the adhesive is not of good quality it will allow shrinkage to split the seam. If the adhesive and synthetic turf is not able to cohere properly to the seaming tape this will cause future failure. Note; Drywall seam tape is not to be used seaming synthetic turf together!

Seaming tape that is manufactured with a plastic film on one side is to prevent moisture from penetrating through the tape and causing delamination within the adhesion. This film is made to be face down on the soil. If it is placed upside down, thermal movement will cause the film to immediately delaminate causing the seam to fail.

Putting Greens & Thermal Movement

Synthetic Turf Putting Greens are very susceptible to thermal expansion and contraction. Putting green materials are not very thick in material which makes them a candidate for thermal movement. When putting greens move causing shrinkage and/or seam rupture, there is only one option, and that is to be removed and replaced.

Ballast is crucial to combating thermal movement in putting greens. Placing the correct infill, size and amount is imperative to controlling movement. Not only is infill used to complete your putting green system for proper rolling of the golf ball, it will assist in keeping thermal movement from damaging the entire installation.

Integrating seams in putting greens prevents movement and gives longevity to the seam. You can order the new Superseam Putting Green Tool at SGW.

“As a synthetic contractor, Thermal Expansion and Contraction can be your worst enemy. Make the first move before… your turf does”

“Ask JW”

Stay tuned for next month’s ‘Ask J.W.’ installment!

For more information regarding thermal expansion and contraction, contact J.W.: askjw@sgwcorp.com or call 888.846.3598