The fibers that make up the blades of synthetic turf grass are usually made from Nylon, Polyethylene or Polypropylene. Blending of special ingredients made from colored pellets give the turf its traditional green color. Added chemicals in the mixture protects the fiber from the ultraviolet rays from the sun. These pellets are melted, blended and can be manufactured in different ways. They can be produced in thin sheets that are cut into strips or extruded through molds to produce fibers with a round, diamond, “W” cross-section. The final extruded results consist of blades that feel and act like natural grass. This completed mixture creates a dye lot.

A dye lot is a record taken during the dyeing of yarn to identify yarn that received its coloration in the same vat at the same time. Yarn manufacturers assign each lot a unique identification number and stamp it on the label before shipping. When installing multiple sections of synthetic turf, all sections MUST BE OF THE SAME DYE LOT, or you will have non-matching color variations.

Prior to ordering multiple rolls for one installation, it is advantageous to let your supplier know that you will need every connecting roll that is ordered to be made with the same dye lot. Even though manufacturers come very close with every extrusion, it is merely impossible for separate runs to be an exact match.

Dye Lot & Repairs

When making repairs or adding sections to previously installed turf, the added sections may not match. If the client of the installation did not receive any leftover remnants, then you will definitely have a dye lot variation. If the project is large in square footage you may want to let the client know it is best to order extra for future minor repairs.

Even if the dye lot numbers match up with the previously installed turf, there may be a slight discolor or dullness due to the length of time the initial installation was placed.

For example; “If you purchase two pairs of white sneakers and worn one pair for a week and then put them up against the second pair that wasn’t worn, they would not match due to the exterior elements, weather and wear on the sneakers surface. So don’t expect the same dye lot to match up perfectly if you store the sitting roll for any length of time and decide to attach it or make repairs to existing placed sections. The exterior environment plays a heavy role in the abrading of the fibers. If you took a clear piece of plastic that you could look right through and scratched it up a bit, it would change the makeup of how that fiber received light and reflection. The same goes with synthetic turf fibers. So be prepared to quickly asses your project regarding future unknown repairs.” JW

Mistaking Dye Lot Issues Vs. Poor Installation Techniques

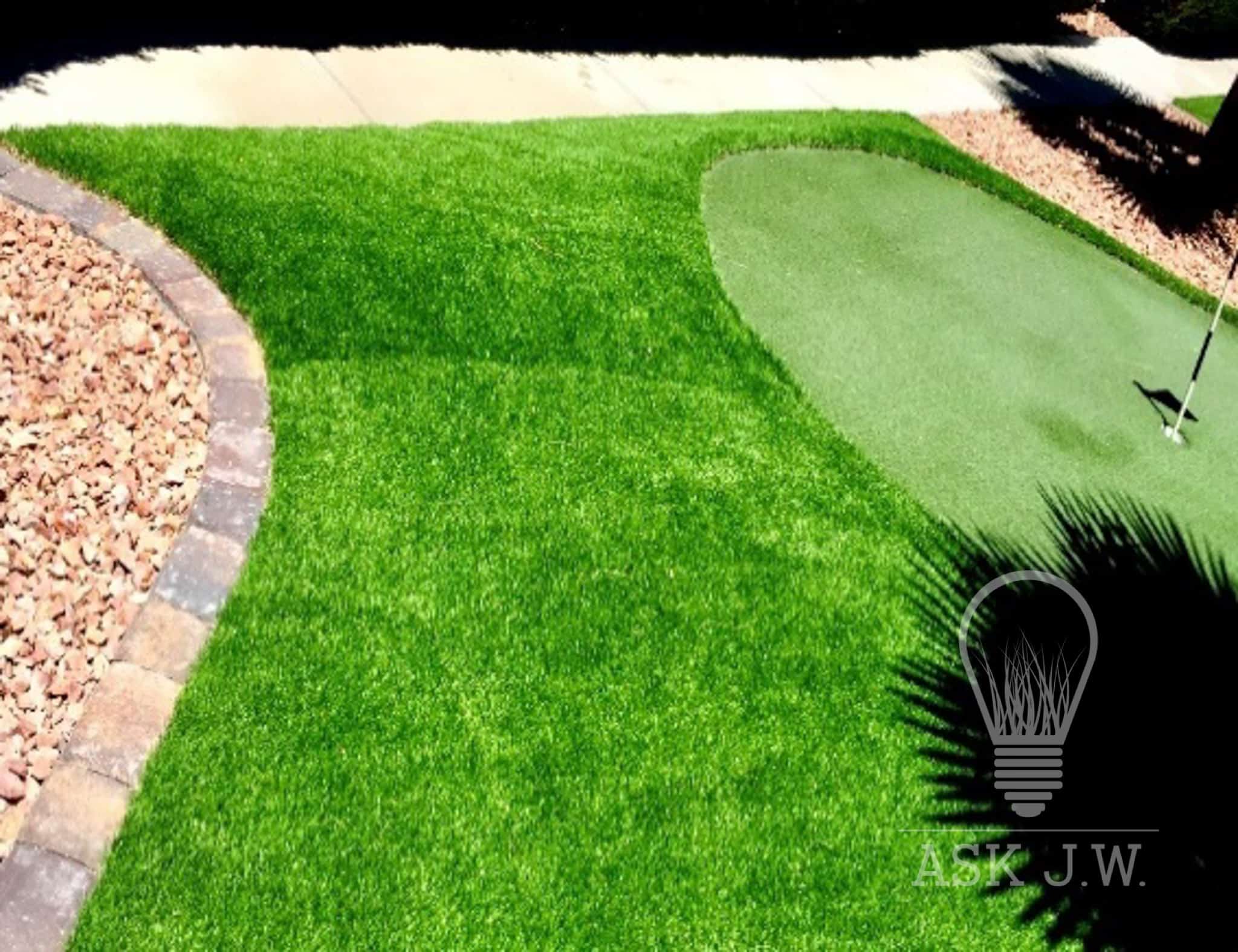

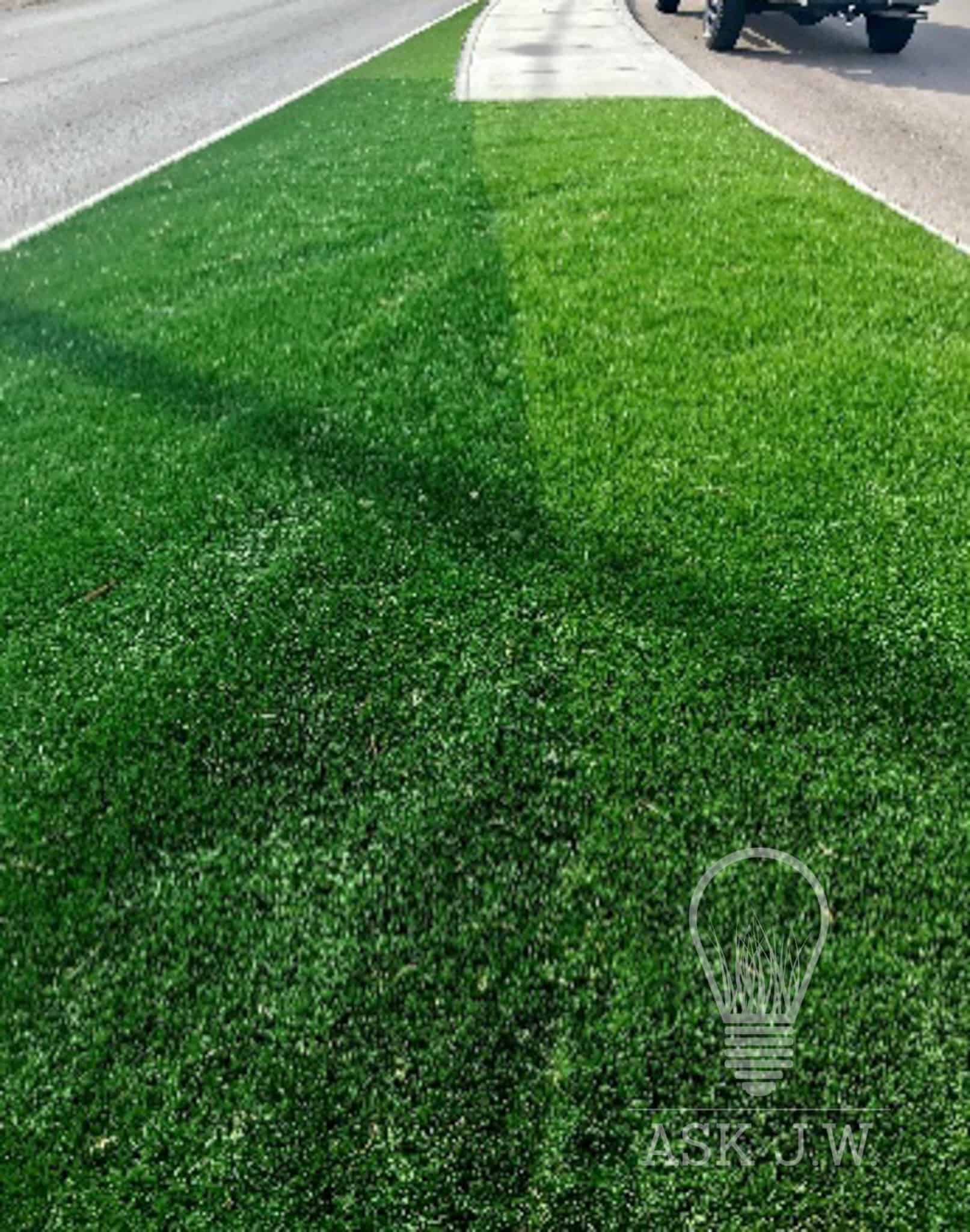

I have witnessed many installations where contractors complain that they received two different dye lots for their project when in fact they had installed the turf on different angles or placed two different rolls entirely. Understanding the alignment of the fibers and its location to connecting sections is crucial.

If the fibers and underlying gauges are not placed in the same direction it may look like a dye lot issue.

“There many facets to being a successful synthetic turf contractor. Understanding dye lot and how crucial it is to your installation can save you time, money and a lot of heart ache of having to remove and replace installations.”

JW

For more information regarding Tucking Synthetic Turf please contact J.W. askjw@sgwcorp.com or call 888.846.3598