Many installers ask “Why can’t I use Zeolite as the primary infill”?

That’s a good question.

Although opinions vary, Zeolite is NOT considered a primary infill because it is not heavy enough to be used as a primary infill.

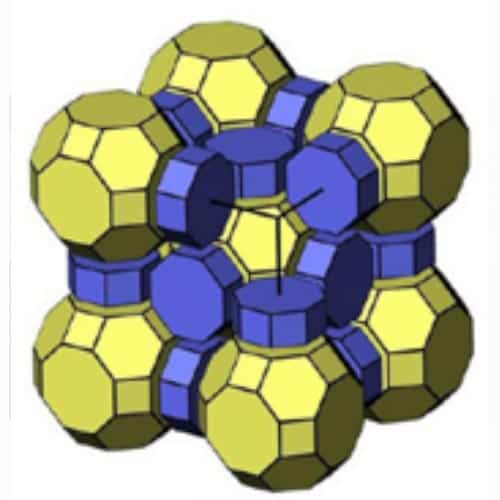

Infill provides stability for synthetic turf. Zeolite is primarily used as an added infill, which is placed under the turf as well as at the base of the fibers to manage odor control. Zeolite is the #1 choice for pet turf areas for odor control. Zeolite is not made to withstand heavy traffic to keep fibers in a vertical state. The granular structure resembles a “honeycomb” appearance and does not constitute a stable grain to be installed as a complete infill. Zeolite should be mixed with SGW Envirofill or SGW Round Premium Silica (RPS) infill.

When Zeolite is wet, it absorbs up to 81% of its original weight in water and 55% of its weight in urine. However, once the granule dries out, it returns to its original state and is not heavy enough to keep the synthetic turf ballasted, which may allow wrinkles in the turf.

Under a microscope, Zeolite resembles a “honeycomb” structure. It is much softer infill than Envirofill or Silica sand. Because Zeolite becomes softer after it absorbs liquids, it is not a good candidate to be used as a 100% infill for synthetic turf.

SGW Envirofill

I recommend to pair Zeolite with Envirofill and let Envirofill serve as the primary infill to ballast synthetic turf. Envirofill is made of a moisture resistant coated silica.

Envirofill is made of an acrylic coated silica sand and repels moistures in addition to unpleasant odors associated with our pets. Because of the anti-microbial coating, Envirofill inhibits the growth of micro-organisms. Envirofill is a colored and sealed silicon dioxide (SiO2) and is free of dust. The rounded, uniformly sized beads reduce abrasiveness to surrounding turf fibers by up to 50 percent while allowing movement within the synthetic turf.

Most silica sand is fractured and angular which causes it to compact easily with heavy rain fall and foot traffic. This may cause premature wear at the fiber’s bending point at infill level. This constant action will create memory loss in your synthetic turf.

Envirofill comes in small and large granules, is available in 50 pound bags and sold exclusively through SGW.

SGW Round Premium Silica (RPS)

SGW Round Premium Silica sand is my second choice for infill. The Round Premium Silica Infill is not a fractured/angular silica and is the latest in silica infill technology.

Product Features:

- Naturally occurring exceptionally round mono-crystalline quartz (silica) resists abrasion in high traffic/ excessive wear application.

- Double washed and screened to ensure uniform size distribution (no dust) and consistent grain shape.

- Dried to less than 0.1% Moisture content before bagging

- Sold in 50 pound bags

- Natural Brown Color

Product Benefits:

- Less compaction than fractured angular silica

- More volume per pound

- Cooler to the touch

- Easy to handle 50 pound bags.

Realistic “soil” look blends nicely with artificial turf thatch–no more white sand drifts.

My recommendations for placing infill in synthetic turf is as follows:

On pet applications, I recommend placing approximately ¼” of Zeolite on your compacted subgrade. Place approximately 1 pound of Zeolite per square foot as the first lift (stages) to the base of fibers, then place 1-1/2 to 2 pounds per square feet of either Envirofill or SGW Silica for ballast.

For synthetic turf that will not experience pet traffic, I recommend placing approximately 1 pound of Envirofill per square foot or 1-1/2 to 2 pounds of RPS sand per square foot. See the turf’s infill requirements on each individual spec sheet. All of SGW’s synthetic turf product spec sheets are available for download on the SGW website, click here to download!

Be sure to broom or rake all infill in steady lifts. If the turf will experience heavy foot traffic, mix SGW Envirofill to allow proper movement of the fibers to prevent premature matting.

By installing infill in lifts (or stages), this will help prevent trapping the turf fibers and ensure a beautiful installation.

When the installation is complete, the infill level should be approximately ½ inch below the fibers.

Stay tuned for next month’s “Ask J.W.” installment! For more information, contact J.W.: askjw@sgwcorp.com or call: 888-846-3598